Tooling designers design, optical coating holding fixtures, for coating optical substrates. Substrates coated to tight tolerances. Or substrates coated at high temperatures. Normally require optical coating holding fixtures manufactured from expensive Nickel alloys, such as Kovar. These have low thermal expansion rates, which are compatible with the substrate expansion rates.

Optical coating holding fixtures below cost of Ni alloy, downloadable calculator

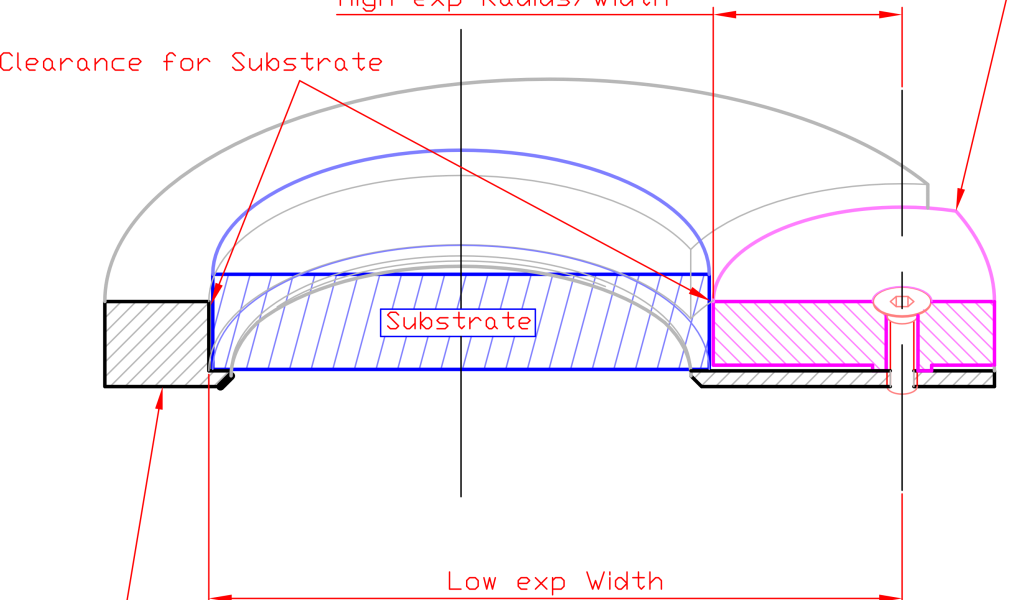

Another approach for the tooling designer is to use bimetal tooling. The thermal expansion of 2 metals is used in opposition, to maintain the substrates location. The designer uses the difference in expansion, of the location features of the substrate holder. To open at the same thermal expansion rate as the substrate itself. The metals used will commonly be stainless steel and aluminium grades. these are considerably cheaper than the nickel-based alloys, such as Kovar. The downside for this is the lower substrate density, as the overall tooling size is larger, but for small quantities, and prototypes, this may not be an issue.

–

Using the Thermal Calculator

Once you download the thermal calculator, in order to solve the optical coating holding fixtures, dimensions.

The designer enters.

The expansion rates for the substrate and proposed tooling materials.

The diameter of the substrate.

The clearance required, between the substrate and tooling location.

These are entered in the yellow boxes on the left.

The temperature difference is then entered in the right yellow box.

The High exp Radius/Width, and the Low exp Width is then given in the blue boxes.

These are the values that the tooling designer adds to the optical coating holding fixtures, dimensions on the tooling drawings.